Model No.︰MCT200

Brand Name︰GRAIGAR OR OEM

Country of Origin︰China

Unit Price︰US $ 396 / pc

Minimum Order︰1 pc

Digital Coating Film Thickness Gauge MCT200

Specifications

Measuring principle:Magnetic induction & Eddy current

Measuring range :(0~1250) μm, depends on probes. maximum 10mm for the probe F10. Refer to Appendix.

Low range resolution:0.1μm

Accuracy: ±(3%Thickness+1) μm, depends on probes and conditions

Display:4 digits LCD with EL backlight

Memory for up to 20 files (up to 50 values for each file) of stored values.

Unit system: Metric (μm),Imperial (mil)

Power source: Two “AA” size, 1.5 Volt alkaline batteries. 200 hours typical operating time (EL backlight off).

Communication:USB1.1

Dimensions:125mm×67mm×31 mm

Weight:340g

Features

* With different external probes, the gauge can be applied to measuring thickness of non-magnetic coating on magnetic metal substrate, as well as non-conductive coating on non-magnetic metal substrate.

* Five types of probes (F400, F1, F10, N1, CN02) are available for different application. F10 probe measures up to 10mm.

* Two measuring modes: single or continuous, changeable.

* Two calibration methods can be applied to the gauge; And the system error of the probe can be corrected with the basic probe calibration method.

* Measured values and user information are shown on a large, easy-to-read LCD. A display back light ensures easy reading of screen data in poorly-lit conditions.

* Measuring status indicator showing the measuring status.

* The gauges’ user-friendly measuring system permits automatic storage of up to 1000 readings in one memory matrix for later statistical evaluation.

* Battery information indicates the rest capacity of the battery.

* Auto sleep and auto power off function to conserve battery life.

* USB1.1 communication port. Optional software to process the memory data on the PC.

* Compact aluminum case,suitable for use under poor working conditions

Measuring Principles

The gauge adopts two thickness-measuring methods: magnetic induction method and eddy current method.

insulating coatings on all non-ferrous metals and on austenitic stainless steels, e.g. paint, anodizing coatings, ceramics, etc. applied on aluminum, copper, zinc die-casting, brass, etc.

Working Conditions

* Working temperature: -10~+50

* Storage temperature:-30~+60

* Relative humidity: ≤90%;

* The surrounding environment should avoid of vibration, strong magnetic field, corrosive medium and heavy dust.

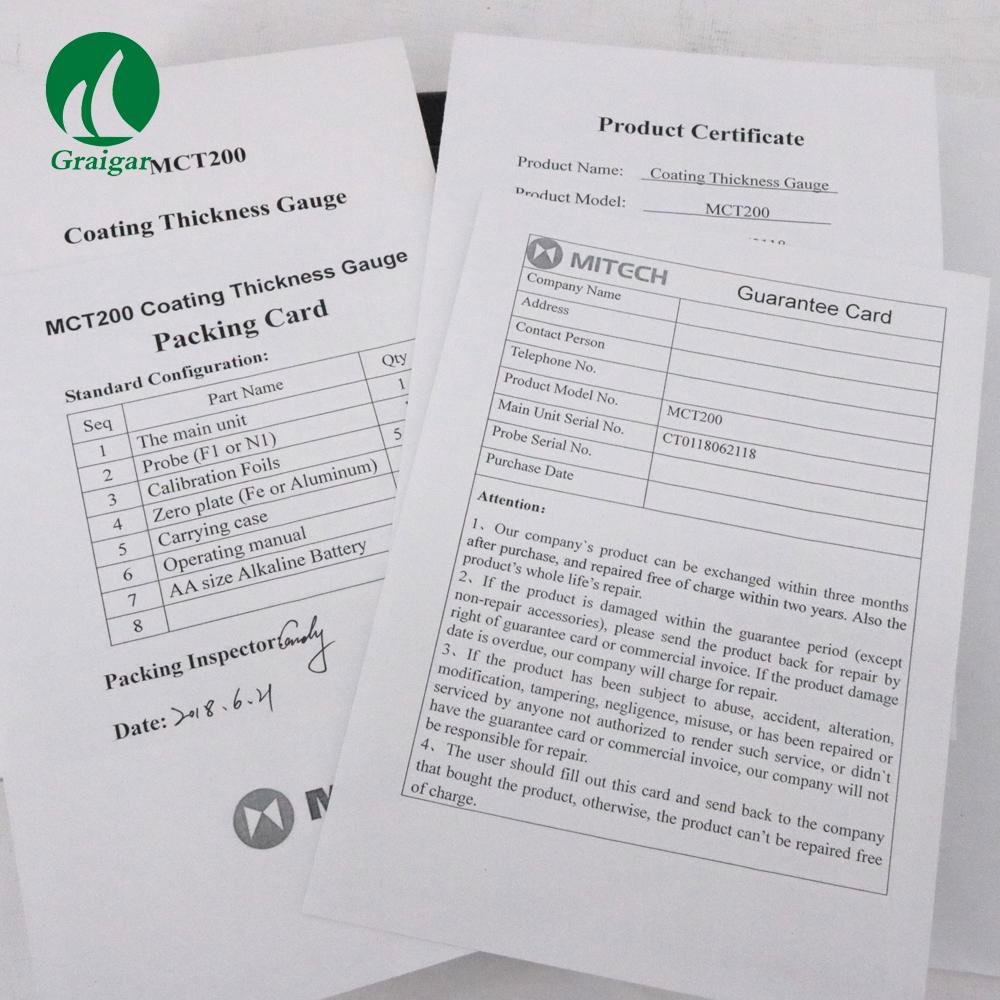

Configuration

|

|

No. |

Item |

Quantity |

Remarks |

|

Standard Config. |

1 |

Main unit |

1 |

|

|

2 |

Probe |

1 |

F1 or N1 |

|

|

3 |

Calibration Foils |

5 PCS |

|

|

|

4 |

Zero plate |

1 |

Iron or Aluminum |

|

|

5 |

Instrument case |

1 |

|

|

|

6 |

Manual |

1 |

|

|

|

7 |

Alkaline Battery |

2 PCS |

AA size |

|

|

8 |

|

|

|

|

|

Optional Config. |

9 |

Other type of probes |

|

|

|

10 |

DataPro software |

1 |

On CD |

|

|

11 |

USB cable |

1 |

|

(Julie Zhou)

Price Terms︰ EXW Shenzhen

Payment Terms︰ TT/LC/Western Union/Paypal

Packing︰ EXPORT CARTON

Lead Time︰ 2 days